Alaabta

-

Mashiinka khad simaynta iyo nadiifinta cadaadiska tooska ah

Tilmaamaha Farsamada

Qaado kontoroolka PLC, qaabka xakamaynta dabacsan oo la isku halayn karo

Laba kooxood oo riixaya rollers, hal ama laba kooxood ayaa loo dooran karaa inay shaqeeyaan isku mar

Saamaynta fidsan ee ku habboon shuruudaha kala duwan

Ogaanshaha tooska ah ee filimka jaban

Isticmaalka interface man-mashiinka, fududahay in la shaqeeyo

-

Nooca qaab-dhismeedka foornada tunnel-ka ayaa gudbisa

PCB, BGA, FPC, COF, Muqaal, Taabasho Panel, Back Light, Solar Cell, Smart Card, Filimka indhaha, Battery iyo Semiconductor.

-

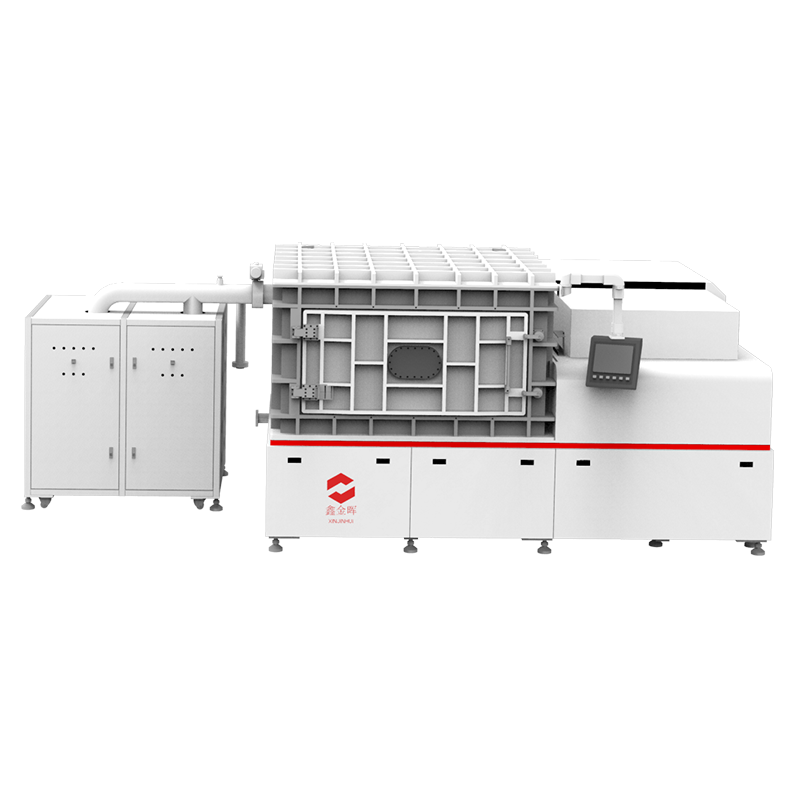

Mashiinka cacuum ee caqliga leh

Mashiinka oo dhan waxa uu ka kooban yahay CCD indheergarad ah nidaamka couterpoint, iyada oo ay nidaamka vacuum u gaar ah fur godka godka, waxa ay ku haboon tahay dalool caag viscosity sare, isticmaalka gudaha iyo dibadda si fiican u yaqaan qaabeynta hardware koronto, qalabaysan fikradda design horumarsan. iyo saamiga qaab dhismeedka farsamada deggan, iyo tiro taageero tignoolajiyada patent.

-

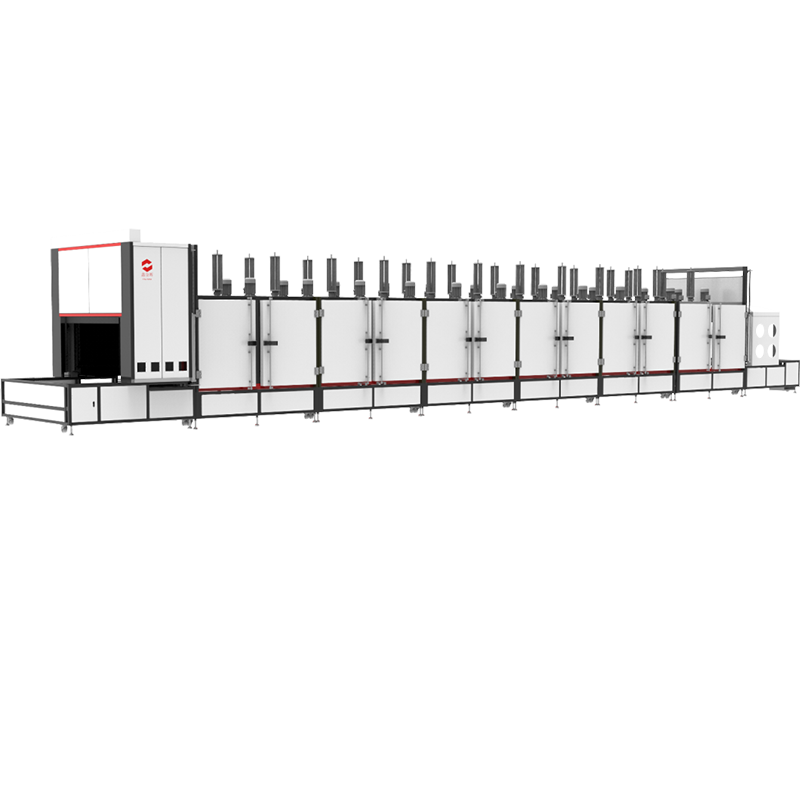

U Nooca IR Tunnel Foornada/Furno qalajinta

Sharaxaada Alaabta

Foornooyinka dib-u-qulqulaya warshaduhu waxay ka kooban yihiin meelo badan oo gaar loo kululeeyay, kuwaas oo si gaar ah loo xakamayn karo heerkulka.PCB-yada la farsameeyay

ku dhex safr foornada oo aag kasta u gudub si xawli ah.Farsamayaqaanadu waxay hagaajiyaan xawaaraha gudbinta iyo heerkulka aagga si ay u gaadhaan waqti la yaqaan

iyo astaanta heerkulka.Xogta la isticmaalay way kala duwanaan kartaa iyadoo ku xidhan shuruudaha PCB-yada laga baaraandegayo wakhtigaas.

Mashiinka oo dhan wuxuu ka kooban yahay qaybta quudinta, aagga qallajinta oo u dhigma nidaamka soo saarista tamarta-badbaadinta ee patented, nidaamka gudbinta hawada, nidaamka ilaalinta kulaylka, iyo qaybta dejinta.Waxay qabataa nashqada gudbinta U-qaababka leh ee la soo dejiyay, hawlgal xasiloon iyo saamayn wanaagsan oo tamar-badbaadin ah.Ku habboon looxyada wareegyada ka horreeya dubitaanka/dubidda ka dib. -

Bog-Laba-Tunnel-ka-rogista Foornada Qaadista

Sharaxaada Alaabta

Foornooyinka dib-u-qulqulaya warshaduhu waxay ka kooban yihiin meelo badan oo gaar loo kululeeyay, kuwaas oo si gaar ah loo xakamayn karo heerkulka.PCB-yada la farsameeyay

ku dhex safr foornada oo aag kasta u gudub si xawli ah.Farsamayaqaanadu waxay hagaajiyaan xawaaraha gudbinta iyo heerkulka aagga si ay u gaadhaan waqti la yaqaan

iyo astaanta heerkulka.Xogta la isticmaalay way kala duwanaan kartaa iyadoo ku xidhan shuruudaha PCB-yada laga baaraandegayo wakhtigaas.

Mashiinka oo dhan waxa uu ka kooban yahay quudinta weecinta tooska ah, aagga qallajinta oo u dhigma nidaamka kuleylka tamarta-badbaadinta ee patented, nidaamka gudbinta hawada, nidaamka ilaalinta kulaylka, iyo isku xidhka tooska ah ee dejinta mashiinka.Waxay qabataa qaabaynta saxanka gaarka ah, hawlgal deggan iyo saamayn tamar-badbaadin ah oo wanaagsan.Waxay ku habboon tahay dhabarka looxyada wareegga dubista. -

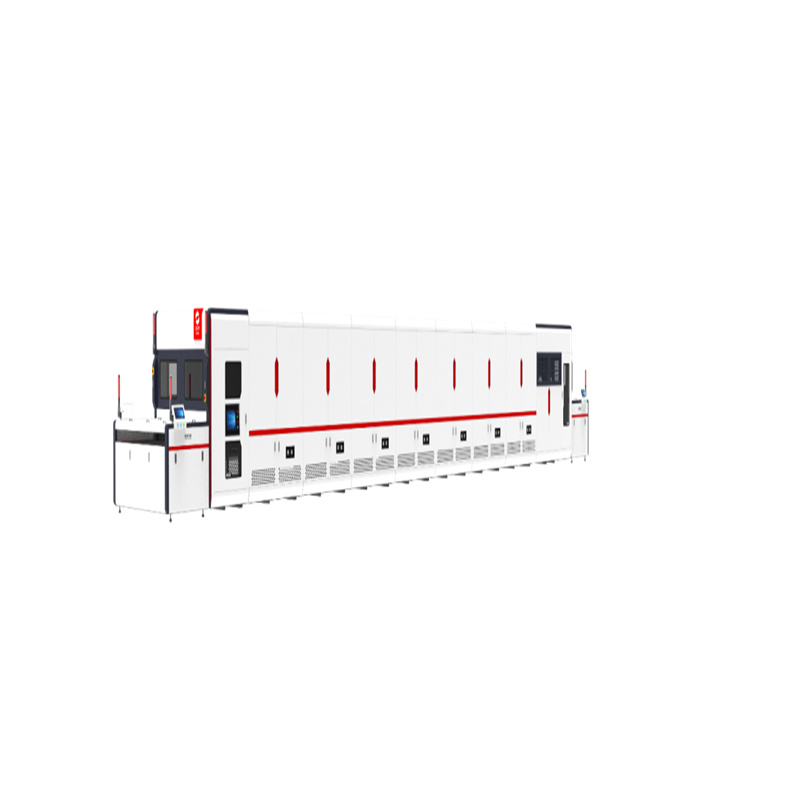

Foornada qalajinta tunnel-ka-sare ee ka laadlaadda

Sharaxaada Alaabta

Foornooyinka dib-u-qulqulaya warshaduhu waxay ka kooban yihiin meelo badan oo gaar ah oo kuleyl ah, kuwaas oo si gaar ah loo xakameyn karo heerkulka.PCB-yada la farsameeyay

ku dhex safr foornada oo aag kasta u gudub si xawli ah.Farsamayaqaanadu waxay hagaajiyaan xawaaraha gudbinta iyo heerkulka aagga si ay u gaadhaan waqti la yaqaan

iyo astaanta heerkulka.Xogta la isticmaalay way kala duwanaan kartaa iyadoo ku xidhan shuruudaha PCB-yada laga baaraandegayo wakhtigaas.

Mashiinka oo dhan wuxuu ka kooban yahay quudinta tooska ah ee manipulator, meesha qallajintu waxay ku habboon tahay nidaamka kuleylka tamarta-badbaadinta ee patented, habka gudbinta hawada, nidaamka ilaalinta kulaylka, iyo quudinta tooska ah ee manipulator.Isticmaalka xirmooyinka cayrinta ee u gaarka ah, hawlgal xasiloon iyo saamayn wanaagsan oo tamar-badbaadin ah.Ku habboon looxyada wareegyada ka horreeya dubitaanka/dubidda ka dib. -

Gaadhi-qaadista otomaatiga ah

sharaxaada alaabta

Mashiinka oo dhan wuxuu ka kooban yahay qaybta rarista, daboolka qaadista iyo qaybta dejinta.Isticmaalka shafka saxan 18mm ee rukhsadda leh iyo naqshadaynta silsiladaha, hawlgal deggan.Waxay ku habboon tahay wareegga wareegga wareegga, qaboojinta iyo kaydinta ku meel gaarka ah. -

Mashiinka Daabacaadda Shaashada Laba-jibbaar

Sharaxaada Alaabta

Mashiinka oo dhan wuxuu ka kooban yahay miisas laba jibbaaran, oo ku habboon wareegga / maaskarada alxanka / habka daabacaadda khad daloolka daloolka, wuxuu qaataa qaabeynta qalabka korantada ee si fiican loo yaqaan gudaha iyo dibaddaba, oo lagu qalabeeyo fikradaha naqshadeynta sare iyo saamiga qaabdhismeedka farsamada ee deggan, waxaana taageeraya Tiro ka mid ah tikniyoolajiyada shatiga leh Hubi wax soo saarka xasilloon oo la isku halayn karo iyo hawlgalka alaabta. -

Laba-Albaabka Toosan Foornada Hawada Kulul

Sharaxaada Alaabta

Meesha qalajinta ee mishiinka oo dhan waxay la mid tahay nidaamka kulaylka tamarta-badbaadinta ee patented, nidaamka dabaysha iyo nidaamka ilaalinta kulaylka.Saamaynta tamarta wanaagsan ee badbaadintaKu habboon looxyada wareegyada ka horreeya dubitaanka/dubidda ka dib. -

Mashiinka Daabacaadda Shaashada ee Semi-autota ah

Sharaxaada Alaabta

Mashiinka oo dhan wuxuu ku habboon yahay habka wax soo saarka khad wareegga / alxanka.Waxay qabataa qaabeynta qalabka korantada ee si fiican loo yaqaan gudaha iyo dibaddaba, waxay ku qalabaysan tahay fikrado naqshadeed oo horumarsan iyo saamiga qaabdhismeedka farsamada ee deggan, waxaana taageeraya tiro tikniyoolajiyadeed oo la aqoonsan yahay si loo hubiyo soosaarka badeecada iyo hawlgalka xasilloon oo lagu kalsoonaan karo. -

Foorno qallajin toosan oo albaab laba-laaban ah oo madax-bannaan

Sharaxaada Alaabta

Meesha qalajinta ee mishiinka oo dhan waxa lagu jaangooyay nidaamka wax-soo-saarka tamarta-badbaadinta ee patented, nidaamka gudbinta hawada, iyo nidaamka daboolka kulaylka.Saamaynta tamarta wanaagsan ee badbaadintaKu habboon looxyada wareegyada ka horreeya dubitaanka/dubidda ka dib. -

Nooca mesh foornada marinka tunnel-ka ee IR

Sharaxaada Alaabta

Foornooyinka dib-u-qulqulaya warshaduhu waxay ka kooban yihiin meelo badan oo gaar loo kululeeyay, kuwaas oo si gaar ah loo xakamayn karo heerkulka.PCB-yada la farsameeyay

ku dhex safr foornada oo aag kasta u gudub si xawli ah.Farsamayaqaanadu waxay hagaajiyaan xawaaraha gudbinta iyo heerkulka aagga si ay u gaadhaan waqti la yaqaan

iyo astaanta heerkulka.Xogta la isticmaalay way kala duwanaan kartaa iyadoo ku xidhan shuruudaha PCB-yada laga baaraandegayo wakhtigaas.

Mashiinka oo dhan wuxuu ka kooban yahay qaybta quudinta, aagga qallajinta oo u dhigma nidaamka soo saarista tamarta-badbaadinta ee patented, nidaamka gudbinta hawada, nidaamka ilaalinta kulaylka, iyo qaybta dejinta.Qaadashada naqshadaynta suunka mesh-ka Teflon ee dibadda laga keeno, hawlgal deggan iyo saamayn wanaagsan oo tamar-badbaadin ah.Ku habboon looxyada wareegga hore loo dubay.